Written by Flavia Gaudio, engineer at Gestione Ed Eserizio del Sistema Tranviario SPA (GEST)

The maintenance of the Florence Tramway System is a challenging task for GEST. The infrastructure is stressed with trams rolling for around 7000 km everyday along the 3 existing lines. In this scenario the “preventive” approach, currently adopted in maintenance, is based mostly on industry averages and best practices, where different kind of triggers determine when to do service to the equipment; these triggers can be specific time interval expiration, defined traveled distance thresholds or the occurrence of specific conditions.

The preventive approach implies the collection, analysis and management of a big amount of information for each component under maintenance, such as equipment age, dates of inspection and service records. Therefore, considering also the future tramway line extensions, an increasing effort in terms of costs, resources and time need to be allocated on these tasks.

Monitoring of key indicators, such as failure events frequencies, operational costs and root causes identification, represent the actual basis on which short-term decisions are taken and long-term strategies are planned.

A step forward can be achieved by the transition from a “preventive” to a “predictive” maintenance approach where processes are refined and intervention frequencies are tuned on the basis of indicators “felt” from the system. This approach implies a revamping of the current equipment with a higher level of technology, such as the installation of IoT sensors and other software and hardware tools needed to collect information considered representative of the true and most updated picture of the system utilisation.

Starting from manuals and guidelines, procedures and activity scheduling can be, thus, optimised on the basis of the actual utilisation of the equipment, focusing also on environmental factors or behaviours that may affect the state of components in an unexpected way

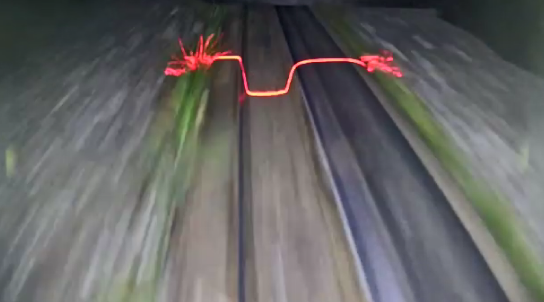

Track affected by severe wear along Tramway Line 1 in Florence. Picture taken before maintenance intervention.

Predictive maintenance can be useful both for validating the current maintenance schedule and fine tuning of the planned strategies by means of: indicators trends monitoring, unexpected faults detection in the early stages of their appearance, and correlation, when possible, with habits in infrastructure and tram usage that could impact significantly on the duration of specific components. Therefore, the maintenance interventions are driven toward the equipment that encounters a significant or anomalous wear rate that may soon brought to a failure.

In the Predictive Maintenance use case, driven by GEST, the attention has been focused mostly on data related to track consumption and energy absorption.

Track and tram components stressing and energy absorption during daily service are crucial factors. Compromising even one of them may bring a sudden and heavy decrease of both safety and efficiency levels and, in worst cases, interruption of the transportation service.

Track profiles are sampled using laser based sensors mounted on the maintenance vehicles, owned by GEST, while energy related data are sampled runtime from specific trams in service equipped with a dedicated unit that captures them directly from the internal system of the tram.

Laser blade generated by sensors for track profile detection while maintenance vehicle is moving.

Once collected, these data are forwarded to the ELASTIC software infrastructure by means of edge devices mounted on board. The exploitation of elastic computing resources distributed both at fog and cloud level can make this data to then be organised, analysed and presented in a useful way by means of a dashboard.

GEST has driven the definition of the analytics requirements that drive the implementation of the ELASTIC dashboard so that the maintenance team can be supported in:

• Defect detection and classification

• Comparison of the collected data with the theoretical/expected ones

• Notifications in case of parameters out of tolerances

• Parameters trend follow up

• Unexpected worsening of parameters identification and alerting

• Definition of maintenance intervention efficacy after its execution

The idea of “feeling” the system through sensors and edge devices establishes a brand-new link between the existing tramway network in Florence and an innovative software infrastructure, whose computing resources speed up innovation via the predictive maintenance approach.